Flaring, belling, expanding are all words which describe the process of opening the mouth of your brass case before attempting to seat a bullet.

If there is one process that is crucial in the loading of our polycoated bullets, it's is the flaring of the case mouth!

Not properly expanding the case mouth can cause numerous issues such as:

There are many different types of expanders, each die manufacturer is different, and there are even variations within each manufacturer. But, in any case, as long as you are able to expand the mouth enough to seat your bullet smoothly and straight, you are in good shape!

If there is one process that is crucial in the loading of our polycoated bullets, it's is the flaring of the case mouth!

Not properly expanding the case mouth can cause numerous issues such as:

- Shaving the coating during the seating process (exposing the lead can cause leading of your bore!)

- Damage to the base or shank of the bullet (possibly causing decreased accuracy)

- Crooked seating of the bullet

- Poor feeding or chambering of your completed cartridges

There are many different types of expanders, each die manufacturer is different, and there are even variations within each manufacturer. But, in any case, as long as you are able to expand the mouth enough to seat your bullet smoothly and straight, you are in good shape!

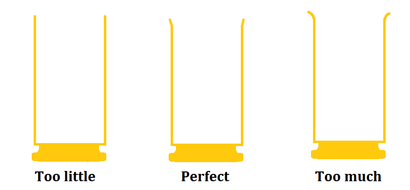

How can you tell if your brass has been sufficiently flared or expanded? If you can set a bullet in the mouth easily and you find no signs of scraping or shaving on the coating after seating your bullet, you have enough flare. But more is not better! When it comes to flaring the mouth, you need to take the Goldilocks approach, it can't be too little or too much, it should be just right.

You should expand the mouth just enough to seat the bullet properly and no more. Not only does too much flaring cause excessive wear on your brass (which can lead to premature failure due to cracking), it can also make your bullets seat crookedly, causing runout and it will likely fail to pass through a case gauge or 'plunk test'. If it's really belled out, you can even feel the brass scraping against the inside of your bullet seating die.

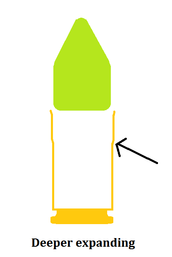

If you wish, certain types of expander dies (like the Lyman M-die, Hornady PTX, or NOE Expander Plugs) will expand more than just the mouth, they will expand further down into the case where the bullet will reside.

This creates a nice deep, straight channel for your bullet to enter. Deeper expanding makes the seating process even smoother and nearly guarantees that your bullets will be seated straight in the case. In addition, the deeper expanding of the case lessens the chance that your bullets will be squished down to a smaller diameter, which can enhance accuracy!

RSS Feed

RSS Feed