While coated pistol bullets are nothing new, coated rifle projectiles are an entirely new animal. Several manufacturers now offer .30 caliber rifle bullets designed for use in 300AAC or 300BLK, specifically for use in subsonic loads in suppresssed guns.

Subsonic means the bullets travel slower than the speed of sound (roughly 1125 FPS), which is a velocity commonly achieved in just about any common pistol caliber. But what about high speed rifle applications? The AR-15 can easily fire 55gr bullets at over 3,200 FPS, almost 3x faster than subsonic loads are traveling. So is it even feasible to attempt loading coated bullets for the AR15?

Subsonic means the bullets travel slower than the speed of sound (roughly 1125 FPS), which is a velocity commonly achieved in just about any common pistol caliber. But what about high speed rifle applications? The AR-15 can easily fire 55gr bullets at over 3,200 FPS, almost 3x faster than subsonic loads are traveling. So is it even feasible to attempt loading coated bullets for the AR15?

| Judging by the photo to the left, we've obviously tried! At the extreme temperatures, pressures, and speeds that rifle cartridges produce, we found some very interesting characteristics, challenges, and promising pieces of data.

|

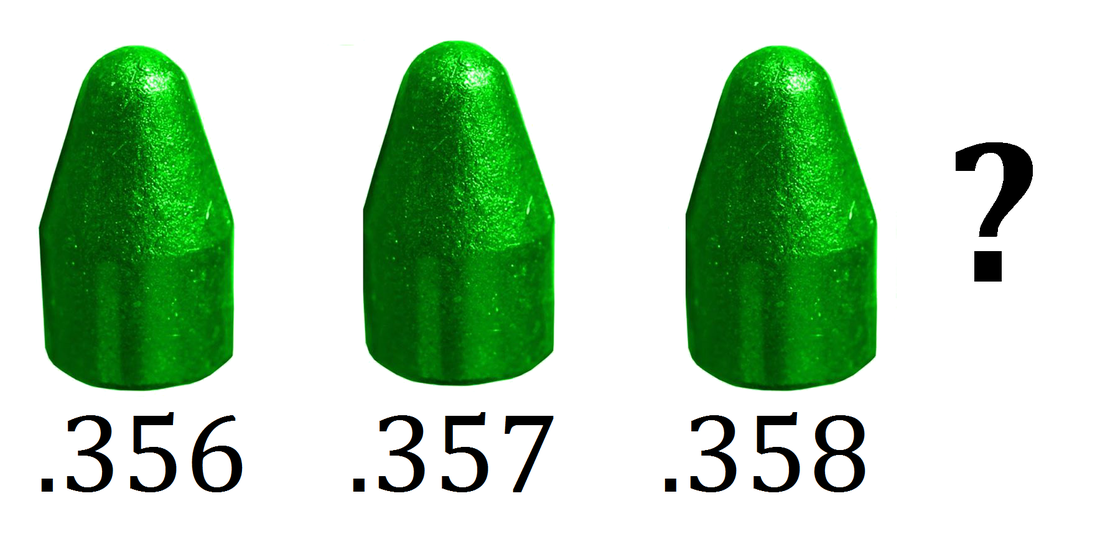

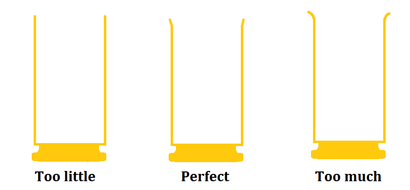

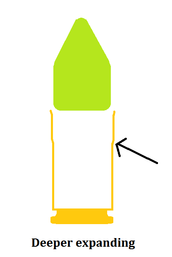

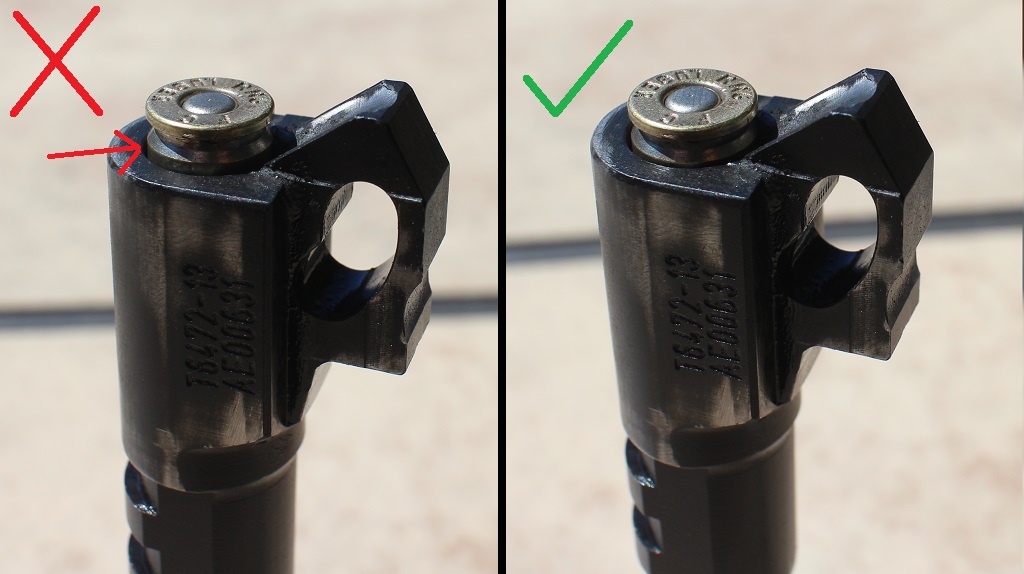

| It became readily apparent that if we wanted to create an accurate & useful rifle bullet, we'd have to push several boundaries. Our goal was to make a bullet that was accurate, easy to load, and would cycle reliably in a semi-automatic rifle. After several iterations of bullet design we went heavy, settling on a 100gr flat point bullet with a small meplat for smooth feeding. We tried 40gr., 55gr., 62gr., 77gr,. and 100gr. bullets and found that the heavier, the better. Heavy bullets move slower, which means you can load them up hot and still stay well under the 2,700 FPS limit that our coating can handle. Heavy bullets also maintain momentum and buck the wind better, which also means they hit harder at range (Think 3-gun rifle spinner targets!). Heavier bullets generate pressure earlier and more easily, which means even a reduced load will cycle your mil-spec AR15 with authority. All-in-all these won't be storming the world of precision rifle where flat trajectories and high BCs are king, but will provide a great and inexpensive alternative which is perfect for 3-gun, tactical rifle matches, and recreational shooting! |

RSS Feed

RSS Feed