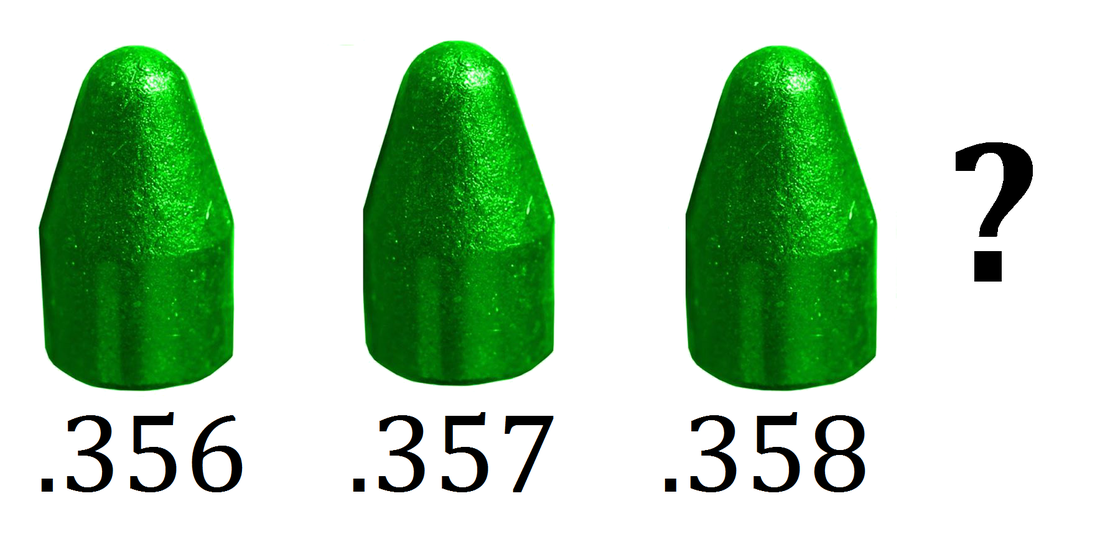

In addition to caliber and weight, a crucial part of selecting a bullet for your load is the sizing diameter. You may have noticed that on our website nearly every single bullet is offered in multiple sizing diameters. With a little research, you've probably learned that every caliber typically has a standard sized bullet diameter (9mm are typically .355 or .356" in diameter, for example). Why are different sizes offered? Because every gun is just a little bit different.

There is an extra wrinkle when you consider that jacketed bullets should be sized differently than plated bullets, which can also be sized differently than cast lead or coated bullets. Why the difference? The primary reason is the hardness of the bullets. Jacketed bullets are the hardest, with cast lead and coated bullets being the softest, and plated bullets are somewhere in the middle depending on how thick the layer of plating is. When firing a cartridge, a cast lead or coated bullet can "squish" down substantially to fit into the bore, so you could run a bullet that's a good bit bigger than the bore! On the opposite side of the spectrum, you don't want to try forcing an oversized jacketed bullet down the barrel, the amount of back-pressure generated could result in a catastrophic failure (AKA a kaboom). Think of coated bullets as a marshmallow, and jacketed bullets as an overcooked piece of chicken breast. You don't want to try swallowing a tough chicken breast without chewing, a marshmallow would make it through just fine!

So with a polymer coated bullet, how do you decide what size bullet to use? A good rule of thumb with cast lead and coated bullets is to measure your groove diameter, and use a bullet that is 0.001" larger. So if your groove to groove diameter is 0.355", use a bullet that is 0.356". The question now is how do you measure your bore and groove diameters? This can be done using a process you can do at home called slugging.

A slug is just a small piece of soft lead: It can be a cast lead or coated bullet, a lead fishing weight (not steel!), or just a round chunk of lead that's roughly the size of your bore (In any case, it needs to be a tiny bit bigger than your bore). Using a rod, push the slug through your bore from chamber to muzzle, you may need to use a mallet if it's a tight fit. Afterwards, you're left with a slug that has been swaged by the barrel, and should have rifling grooves cut into it. The measurement to take with your calipers is the larger overall diameter of the slug, not the smaller diameter from land to land. The overall diameter of the slug will be your actual groove diameter', the smaller diameter is your actual bore diameter.

So with a polymer coated bullet, how do you decide what size bullet to use? A good rule of thumb with cast lead and coated bullets is to measure your groove diameter, and use a bullet that is 0.001" larger. So if your groove to groove diameter is 0.355", use a bullet that is 0.356". The question now is how do you measure your bore and groove diameters? This can be done using a process you can do at home called slugging.

A slug is just a small piece of soft lead: It can be a cast lead or coated bullet, a lead fishing weight (not steel!), or just a round chunk of lead that's roughly the size of your bore (In any case, it needs to be a tiny bit bigger than your bore). Using a rod, push the slug through your bore from chamber to muzzle, you may need to use a mallet if it's a tight fit. Afterwards, you're left with a slug that has been swaged by the barrel, and should have rifling grooves cut into it. The measurement to take with your calipers is the larger overall diameter of the slug, not the smaller diameter from land to land. The overall diameter of the slug will be your actual groove diameter', the smaller diameter is your actual bore diameter.

What's another way to determine the ideal size for your firearm? An equally good method is to simply test various sizing diameters, we offer small sample packs for exactly this purpose. After loading, there are 2 aspects to look at during testing: How smoothly the ammo feeds and chambers, and the accuracy of the loads. In a 9mm, a .358" bullet may give you phenomenal accuracy, but if you have a tight chamber your ammo is having a tough time feeding and seating into the chamber, it's probably not worth the reliability trade off. Likewise, a .356" bullet might feed perfectly, but the groups it shoots may not be as tight. Find the right balance, and you'll find a load which matches your particular gun and gives you the best possible performance.

RSS Feed

RSS Feed